SMC CUSTOM DESIGN & ENGINEERING SERVICES

Navigating complex projects can be challenging, particularly when you are in search for a tailored solution to meet your project requirements. When standard solutions don’t fit, SMC Custom delivers.

Many suppliers tend to specialise solely on design or manufacturing, which can lead to gaps in functionality and integration, resulting in a disjointed experience that may not fully meet your specific needs. You want to find a trusted supplier capable of delivering a reliable, quality end-product seamlessly, from initial concept to deployment.

What is smc custom?

From feasibility to full-scale production, SMC Custom is the specialist design, prototyping, and testing service from SMC Group created for clients with complex integration projects helping to de-risk projects early, accelerate delivery, and ensure performance excellence under pressure.

Design and manufacturing

ISO 9001 Accredited

ISO 27001 accreditation

Integrated Manufacturing Systems

CAD and FEA Design

Complete Radio Systems Testing

Audited Export Control Procedures

Spares and After Sales Service

Full Technical Support for Products in the Field

why choose smc group?

- Assured problem resolution

- Confidence in performance and delivery

- Long-term cost-efficiency

- Scalable and flexible production

- Quality design and manufacturing

- Long-term value in partnership

How it works

phase 1

UNDERSTANDING YOUR REQUIREMENTS

Every enquiry is carefully reviewed to understand your requirements, assess feasibility, and determine the best path forward.

For clients looking to adapt or modify an existing SMC Standard design, we’ll evaluate how that product can be customised to meet your operational needs.

For larger-scale or more complex integration projects, our expert team will define a technical scope of work and prepare a detailed Request for Quotation (RFQ).

This may include:

- Technical concept evaluation

- Preliminary design inputs

- Budgeting and timeline estimates

phase 2

DESIGN, PROTOTYPING & TESTING

Before making a significant investment, it’s essential to ensure you have the right product for your application.

Design

At the concept stage, we collaborate with you to develop custom technical drawings and produce functional prototypes for testing and evaluation. This early-stage process allows you to assess performance, provide feedback, and refine the design – helping to protect your investment and ensure the final product is a perfect fit for your application.

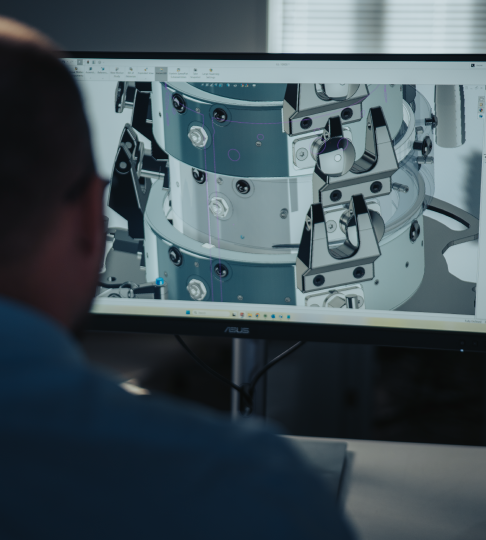

From idea to CAD, our team transforms concept into a working 3D model that’s ready for prototyping and testing. We prioritise manufacturability and field performance from the start.

- Collaborative concept development

- 3D CAD design and modelling

- Design for Manufacturability (DfM) reviews

Once you’re ready to move forward, our in-house design and engineering teams work closely with you to take the project from concept to completion. Through a structured and transparent development process, we validate designs, minimise risk, and streamline the path to full-scale production and deployment.

Prototype and Test

We can build you small-batch prototypes to validate both the design and the product’s real-world performance. Every prototype undergoes mechanical and functional testing to ensure it meets expectations before scaling.

- Single or small batch prototype builds

- Mechanical and functional validation

- Performance assessment and design refinement